Our Process

Design Thinking

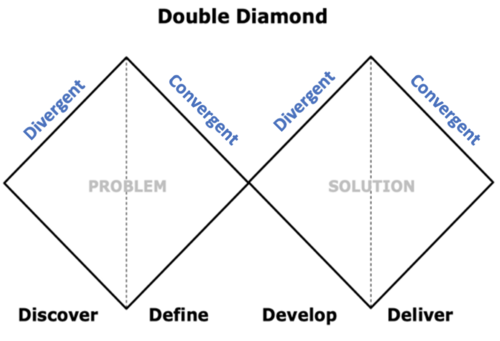

Innovative Problem-Solving: Unleashing Potential Through Design Thinking.

Industrial design is a strategic and creative process that integrates form, function, and aesthetics to conceive and develop products or systems. It involves a systematic approach that combines artistic sensibility with practical problem-solving to meet user needs and market demands. Design thinking, a key component of industrial design, employs empathy, ideation, prototyping, and testing to iteratively solve complex problems, fostering innovation and user-centered solutions.

01.

Interview Experts

Experts in the field of the proposed project is always the best place to start. You don’t know what you don’t know.

02.

Market Research

What already exists that solves our problem? Does it? Is there a market gap for a new product?

03.

Research

Having begun to really wrap our heads around the problem set we know a little bit more about what we don’t know! Let’s dig deeper: interviews, surveys, observations and on and on… narrowing our focus.

04.

Define Problem

This is simple yet critical step. Sometimes we have to help the customer understand their real problem to help develop their solutions.

05.

Ideate Solutions

Now that we know the problem, we can begin to find solutions to solving it.

06.

Sketch Concepts

We narrow our ideas into core concepts. Usually this means finding creative ways to merge concepts.

07.

CAD

At this venture we love our Solution, but there’s a lot to be worked out still. We begin the tedious process of bringing it to life with the help of Computer Assisted Design.

08.

Prototyping

Lets build something to validate our solutions. There are three types of prototypes; functional, aesthetic, and complete. 3D printing is often at the core of this step.

09.

Consult Engineers

We’re ready to think about manufacturing or implementing our new found solutions. We want to consult with industry experts to validate and tweek our solutions. We also have engineers on staff.